FAQs

Preliminaries

On every product page there is a price calculator that will allow you to see all pricing and options included for that product. This will allow you to make the best decision for yourself on whether or not a product is right for you.

Creating an account is easy. At the top of the page there is a link that says Login/Register or you can go right to the user registration page here.

We offer pricing tables on many of the product pages with the base cost and then a variety of upgrade options with the cost to upgrade for that quantity. If there is no pricing table you can always use the pricing calculator at the bottom left of every page for both product pricing and shipping pricing.

If you use any of our free templates on offer, this should remove most of the work for you besides filling out your information and just adding a picture or logo.

Simply, printing turnaround time is the amount of full business days an order takes to print. This is counted separately from shipping time as customers on some products and quantities can pay extra for the order to be printed in less business days. For orders printed on Next Business Day and Same Day Turnaround, they must be submitted before 8AM EST of that day and 11AM EST for orders on 2-4 Business Day Turnaround and 5-7 Business Day Turnaround for that day to count.

Shipping time works as well on business days and is an addition to the printing turnaround time. Ground is roughly 2-3 business days and is handled by UPS.

Please do keep in mind that while we do our best to get our orders out on time, there are a variety of factors that can interfere with meeting these expectations. Do allow an extra business day or two when you order these for any deadline you may have. If you have questions about a specific in-hands-date, email us at support@1800businesscards.com with details, so we can properly inform you before purchase.

General Questions

If you have created a design and want to use it for “Suede” cards instead of “Standard” all you have to do is, go to “My Designs” under “My Account”. When you see your design, click on the option “Create Another Version” and follow the instructions.

We check every uploaded file to ensure it is ready for printing. Uploading the original files is always a good option just in case you sized it incorrectly or if the file requires a minor adjustment, however, a PDF, Illustrator, or Photoshop files are preffered in this case. You can find the required size on every product upload page as well as our template that you can just drop your design in to ensure it is sized correctly.

We require files that are 300dpi, anything less will result in a degraded printing.

In the printing industry it is very possible to have slightly more or less of the purchased quantity. The acceptable industry standard is plus or minus 10 percent. At 1800businesscards we strive to get every order as close to the quantity as possible or more but occasionally the quantity might be less. If you find your count is off an unacceptable amount please reach out to us and we will gladly take the necessary steps to ensure you are a satisfied customer whether that results in sending additional cards or refunding the dollar amount of cards not sent.

Overprinting is used mainly for inks that overlap and can deliver unintended results. In order to avoid issues like the one below please turn off overprint objects when uploading a file. In the below example the background colors were mixed with image.

30mil Plastic/Clear Cards

Just let us know in the “Special Instructions For Order” section of checkout. This is free of charge. We will make sure the design is properly set up upon order, so there is no need to make any design adjustments.

White backing is a layer of white ink that is placed behind just about all logos, content and text unless we are specified otherwise. Without white backing, the content is very hard to see at almost any angle as well as having a translucent “film strip” look. By default all content is white backed. You can let us know otherwise in the section “Special Instructions for Order”.

In short, when printing with clear, the white ink needs to have a hard line to stop. Gradients are by design supposed to blend out of one color and into another. So, technically there is no “edge” that will look natural when stopping the white ink. There are exceptions and these are things we catch before they go into print. You will be contacted if we find major design issues.

In order to have things visible, the white backing needs to be able to cover what's behind it. Things like thin fonts can have the white ink bleed past the intentional area since they are so small and this can create a lower quality looking card. Having thin content can also make it hard to read when being held at certain angles. The way to get around this is to use thicker fonts or increase the size of the content. These are things we catch and try to fix before they go into print. Your order will be placed on hold if we find major unavoidable design issues.

We have what is called a one time Die Cut fee that will allow a customer to attain the custom nature they want. Unless you’ve ordered these custom shapes with us before, please email support@1800businesscards.com with all the specifications, measurements, design files and other possible information. This way we can properly bill for the custom nature and ensure that we get the print of your custom cards right.

Credit cards have a measured thickness of around 35mil. This mostly due to it being a specific plastic material that includes other things within its core. 30mil cards are the highest thickness printers that print plastic cards will carry. These are still great quality and will leave nothing less than a great impression to anyone who receives these.

Darker colored text sitting behind transparent areas can be hard to look at certain angles. The workaround for this is, you can design an area of a colored background that will help make everything within the area easier to read and see.

By default any of the blank white background areas of the design will be counted as clear in most circumstances. Feel free to let us know in the section of checkout labeled, "Special Instructions for Order" if there is somewhere more specific in regards to the clear area.

Occasionally clear plastic business cards can have some of the front and back of the pile cards scratched during transit, but it usually is just a few cards. For this reason we try to add a extra as well as take every step to ensure that cards are packaged correctly.

Designing

Every order that we receive is 100% looked at before going into print. Our production team cleans up, moves, and adjusts to ensure things print correctly. While we do check for design mistakes, we will not able to catch any wrong personal information (address’, phone numbers, LIC#). We are not liable for mistyped information.

If you are uploading designs, you should always use CMYK color mode. When sending an RGB file there is a possibility that the color may shift slightly so try to create files utilizing the CMYK color mode. Below you can see example color differences.

Our system automatically sizes files correctly but if you send your own files please size you files based on the size details on every product upload page. Please remove all crop and bleed marks. Most of our products require a bleed by adding .125" to document length and also .125" to the width and make sure all colors or images flow to the end of the canvas.

Borders can be very difficult to cut exactly how it appears in the design because we do bulk cuts so there is always the chance of the borders not being exactly distributed after the cut. If you require a border on your printed item we recommend that you keep it as far away from the cut lines as possible. Cutting large sheets can result in slight variations throughout the batch. Your order can be cut up to .125" off which is standard in the industry and not considered a manufacturer's error so if you do require a border for best results keep it as far from the cut line as possible.

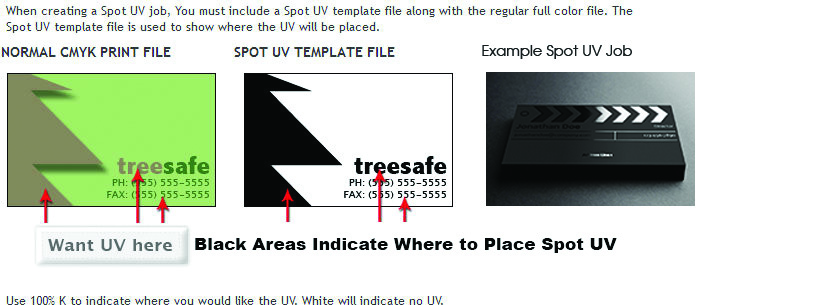

Spot UV is a shiny gloss applied only to certain areas of your design that you choose. In order to get a spot UV job you must create a duplicate version of your card and make 100% black all the areas that you want the UV gloss applied to and submit the file before or after your order to support@1800businesscards.com. Just include your order # in the email with your attachment. See the details about file preparation below.

While we do offer a lot of sizes and we are always expanding them, many are not standard. We keep a variety of templates for the most common of sizes relative to the product. In some product cases, we will allow an upload only option. Many companies or groups will know the product we already have on offer and keeping a catalog of templates will only serve to confuse our clients.

Making sure your blue remains blue, and doesn't appear as a purple. If you decide to use blue in one of your designs you should try to leave at least a 30 percent difference in the Magenta and Cyan values. Because purple and blue are very close in CMYK coloring, utilize a small amount of magenta when utilizing a high amount of cyan. C100%/M70%

On a Computer Screen Printing Completed

Darker colors like black are prone to edges cracking, however, this usually occurs in a small amount of the run. In order to avoid this utilize lighter colors around the edges.

Printing

You can usually request an edit or place it on hold roughly only after a few business hours after the order has been placed. If your order is under the status “In Printing Process” we may rarely be able to stop it. If an order is marked as “Shipped” there is nothing that can be done. You are more than welcome to reach out to our Customer Support team via email or call us during business hours M-F to do this. Please note that by placing an order, you accept that the submitted design is correct and that we do not hold any liability for missing or incorrect designs. Please see our terms and conditions for full details.

Pictures or logos are usually at poor quality or resolution. The workaround with this either uploading a higher resolution version or using an entirely different one if possible. We do try to catch these when we receive them, but please ensure that you are uploading the highest quality when possible. For designers, 300 dpi is what we optimally look for in any image.

When cutting business cards occasionally a card will get cut .125" off. This has very little effect when there is no border but when there is a border that is thin around the edges it will make it easy to see the difference. Because this can occur we recommend keeping borders far from the edge of the card so that they are thick or images with reasonable space on the sides. A cut of .125" off is not considered a manufacturer's error so please adjust your designs accordingly.

Most coated printing products that have scoring can begin to crack. As time goes by the cracking can also expand and lose ink with further use. By not ordering coating can reduce cracking but may not entirely eliminate it.